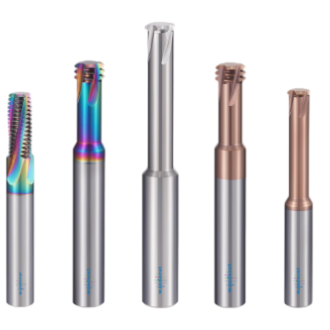

The Thread End Mills for Steel (Whole Teeth) are high-quality cutting tools specifically designed for threading operations on steel materials. These end mills feature whole teeth design, providing excellent cutting performance and chip evacuation. With their advanced features and specialized design, they deliver exceptional performance and efficiency when machining threads on steel.

Key Features:

- Premium Quality: The Thread End Mills for Steel (Whole Teeth) are manufactured using top-grade materials, ensuring durability, longevity, and reliable performance in demanding threading operations involving steel.

- Whole Teeth Design: These end mills feature a whole teeth design, providing maximum cutting efficiency and stability. The whole teeth design enhances chip evacuation, reducing the risk of chip clogging and promoting smooth threading operations on steel materials.

- High-Speed Steel (HSS): The end mills are made of high-speed steel (HSS), a material known for its excellent hardness, toughness, and heat resistance. This ensures long tool life and allows for high-speed machining, enhancing productivity in steel threading applications.

- Thread Profile Options: The Thread End Mills for Steel (Whole Teeth) are available in various thread profiles, including metric and imperial measurements. This allows for the creation of different thread types, such as coarse or fine threads, providing versatility for a wide range of threading requirements.

- Versatility: While designed specifically for steel threading, these end mills can also be used for other ferrous metals, including stainless steel and cast iron. Their versatility makes them suitable for industries such as automotive, aerospace, and general metalworking.

- Compatibility: The Thread End Mills for Steel (Whole Teeth) are designed to be compatible with standard milling machines or CNC machining centers. They can easily integrate into existing machining setups, offering hassle-free installation and operation.

Valoraciones

No hay valoraciones aún.